Mold manufacturing serves as the backbone of global industry, transforming raw materials into complex components for sectors ranging from automotive to healthcare. This article explores the specialized technologies behind automotive parts mold, electronic mould, blowing moulding tools, die casting molds, and medical tooling—highlighting their unique challenges, innovations, and critical roles in modern manufacturing.

The automotive industry demands molds that withstand millions of cycles while producing high-precision components. Key advancements include:

High-Temperature Tooling: Materials like H13 tool steel (hardness HRC 50–55) and beryllium copper are used in automotive parts mold for under-the-hood components, resisting thermal fatigue from engine heat.

Multi-Cavity Design: Modern molds for plastic interior trims can feature 64+ cavities, enabling mass production with cycle times as low as 20 seconds.

Surface Texturing: Electrochemical machining (ECM) creates micro-textures on automotive parts mold surfaces to replicate leather grain or anti-slip patterns, eliminating post-production finishing.

Sustainability Trends: Bio-based polymers like PLA are increasingly used, prompting mold manufacturers to adopt corrosion-resistant coatings (e.g., PTFE) to prevent material degradation.

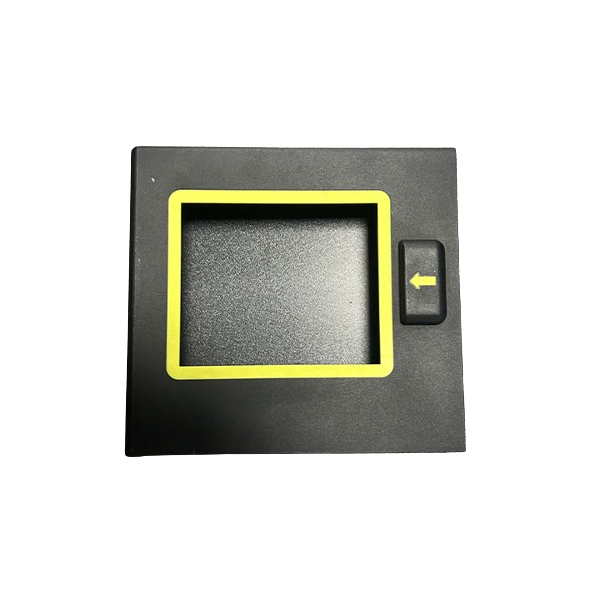

Electronic moulds cater to the electronics industry’s demand for sub-millimeter components. Key innovations include:

Micro-Injection Molding: Tools with 0.1mm-thin walls produce connectors for smartphones, using PEEK and LCP materials that withstand reflow soldering temperatures (260°C+).

Insert Molding Integration: Molds for smart sensors integrate metal inserts and PCB traces in a single shot, reducing assembly steps.

Cleanroom Compatibility: Class 100 cleanroom-certified electronic moulds use stainless steel (316L) and electropolished surfaces to prevent particle contamination in medical device electronics.

Additive Manufacturing: 3D-printed aluminum molds (via SLM) enable rapid prototyping of micro-components, cutting lead times from weeks to days.

Blowing moulding tools excel in creating hollow parts for packaging and industrial applications:

Extrusion Blow Molding (EBM): Tools for HDPE water bottles use split-cavity designs with air channels for uniform wall thickness (tolerance ±0.05mm).

Injection Blow Molding (IBM): Precision tools for pharmaceutical vials achieve neck diameters as small as 3mm, with surface finishes (Ra <0.2μm) to meet USP Class VI standards.

Co-Extrusion Tools: Multi-layer molds for food packaging combine barrier layers (e.g., EVOH) with PE, extending shelf life without additional processing.

Sustainability Focus: Recycled plastics (rPET) require blowing moulding tools with anti-adhesive coatings to prevent contamination from regrind impurities.

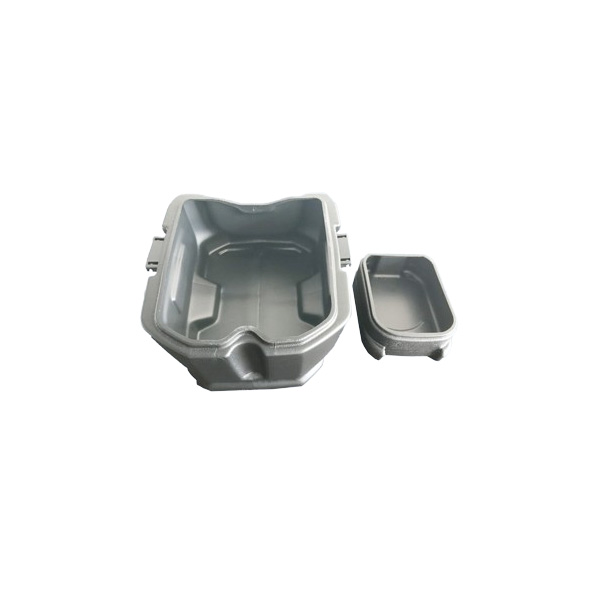

Die casting molds enable high-volume production of complex metal components:

Hot-Chamber vs. Cold-Chamber Tools: Hot-chamber molds for zinc alloys operate at 400–450°C, while cold-chamber tools for aluminum withstand 700–750°C, using H13 steel with nitrogen quenching for durability.

Vacuum Die Casting: Tools with integrated vacuum systems reduce porosity in automotive engine blocks, achieving tensile strengths up to 350 MPa.

Insert Molding for Metal-Plastic Hybrids: Molds that overmold plastic onto aluminum brackets for e-bike components, eliminating fasteners and reducing weight by 30%.

Digital Tooling: AI-driven predictive maintenance (via IoT sensors) monitors die temperature and wear, scheduling maintenance before defects occur.

Medical tooling must meet the highest standards of precision and biocompatibility:

ISO 13485 Compliance: Tools for syringe barrels use electropolished stainless steel (316L) with surface finishes (Ra <0.1μm) to prevent bacterial adhesion.

Multi-Shot Molding for Drug Delivery Devices: Molds that integrate elastomeric seals and plastic housings in two shots, ensuring leak-tightness for insulin pens.

Additive Manufacturing in Prototyping: 3D-printed stainless steel molds (via DMLS) for low-volume medical devices, reducing tooling costs by 60% compared to traditional machining.

Traceability Systems: RFID tags embedded in medical tooling track every production cycle, enabling full regulatory compliance (e.g., FDA 21 CFR Part 820).

Digital Twin Technology: Virtual replicas of automotive parts mold and die casting molds simulate thermal stress and cycle life, optimizing designs before physical production.

AI-Powered Process Control: Machine learning algorithms adjust injection parameters in real-time for electronic moulds, reducing scrap rates from 5% to <1%.

Sustainable Tooling Materials: Biodegradable mold release agents and water-based coolants are replacing petroleum-based products in blowing moulding tools and injection molds.

Collaborative Robotics: Cobots assist in loading inserts for medical tooling and die casting molds, improving operator safety and precision.

As industries from automotive to healthcare embrace electrification, miniaturization, and sustainability, automotive parts mold, electronic mould, blowing moulding tools, die casting molds, and medical tooling will continue to evolve. The integration of smart technologies, advanced materials, and cross-industry innovation will drive mold manufacturing toward greater precision, efficiency, and environmental responsibility—ensuring it remains the cornerstone of modern industrial production.

By balancing sector-specific requirements with universal technological advancements, mold manufacturers empower global industries to transform ideas into reality, one precision tool at a time.