Menu

- Home

- Products

- Mold Industry Design

- Rapid Prototyping

- Mould Manufacturing

- Plastic Injection Molding

- One Stop Service

- News

- INDUSTRY NEWS

- COMPANY NEWS

- Case

- Factory Show

- Prototype Injection Molding

- ISO 9001 Certified Factory

- Strict Quality Check

- Various Injection Machines

- High-Quality Tooling

- Contact Us

- About Us

- Company Style

- Certificate

- VIDEO

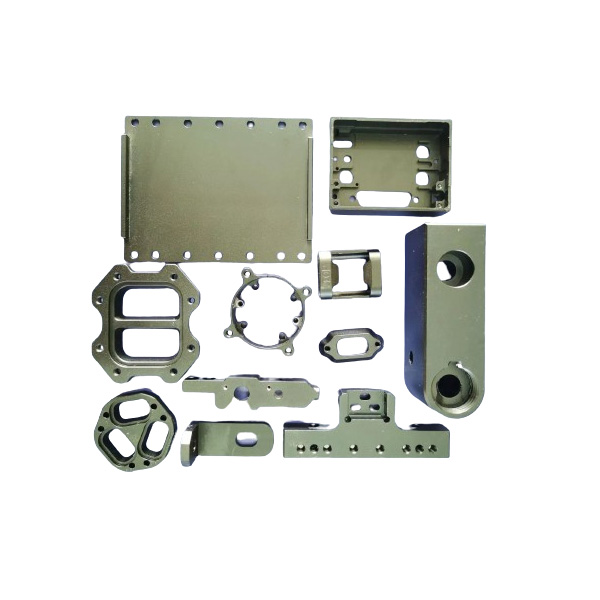

- Industrial automation solutions

Search