One-stop plastic mold engineering design service—a four-step approach from concept to mass production

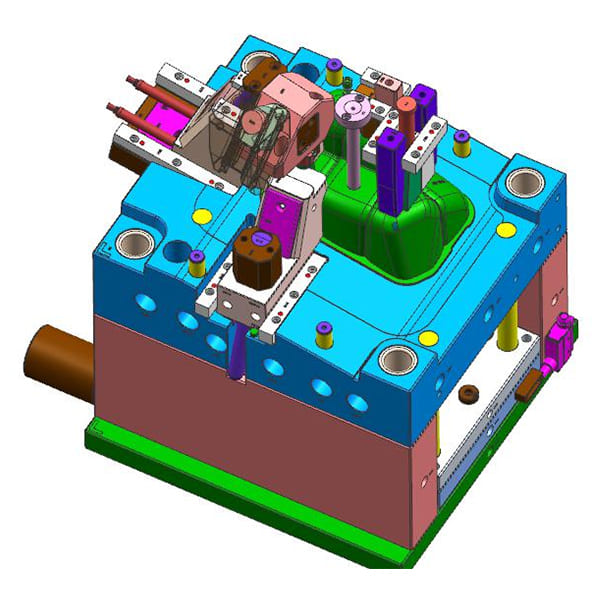

In the field of plastic injection molded parts, if you want to not only meet high-performance requirements, but also achieve efficient and low-cost mass production, you must design from the source. Our "Plastic Mold Engineering Design" service integrates the four modules of engineering design, 3D mold design, tooling design and mold DFM design, and adopts a rigorous four-stage process to ensure excellence in every step from creative prototype to mass production mold.

Project Analysis and Requirements Definition

• Feasibility assessment: Conduct a comprehensive feasibility study based on the parts’ usage environment (temperature, corrosion, load) and industry standards (automotive, medical, home appliances, etc.);

• Requirements sorting: communicate in depth with customers to clarify core indicators such as dimensional tolerances, surface quality, strength and lifespan;

• DFM pre-review: Conduct preliminary manufacturability assessment of mold DFM design, identify potential risks such as wall thickness, draft angle, exhaust, etc., and lay the foundation for subsequent design.

Material and process selection guidance

• Material solutions: From engineering plastics, functional polymers to composite materials, we combine cost and performance requirements to formulate the best selection;

• Process matching: Based on 3D mold design requirements, propose process paths such as injection molding, CNC processing, additive manufacturing or soft mold prototypes;

• Cost balance: Introduce professional consulting from tooling design to optimize mold steel, life requirements and processing accuracy to achieve the best balance between performance and cost.

2D/3D CAD design and mold integration

• Three-dimensional modeling: Use SolidWorks, UG and other software to build parametric parts and mold models, and bury the parting line, cooling water channel and ejector mechanism in advance;

• Engineering drawing: Output 2D drawings with GD&T tolerance annotations to ensure that the tooling design team has a clear understanding of mold processing and tolerance stacking;

• Virtual simulation: Use Moldflow and finite element analysis to verify melt flow, warpage, and stress distribution, and optimize 3D mold design and DFM details.

Rapid trial production and feedback iteration

• Rapid prototyping: restore the final shape of injection molded parts through SLA 3D printing, CNC soft mold or small batch soft mold trial production;

• Functional testing: Perform assembly, strength, heat resistance and appearance testing, and collect actual measurement data;

• DFM improvement: Combined with trial production feedback, adjust the mold DFM design plan to address issues such as demoulding, ejection, and cooling uniformity;

• Delivery report: Provide a complete design report including tooling parameters, mold processing instructions, and injection molding process conditions to help customers seamlessly transition to the mass production stage.

Service advantages

Full process integration: engineering design → 3D mold design → tooling design → mold DFM design, design and manufacturability are advanced simultaneously;

Controllable precision: PLC-level quality management system, mold processing accuracy ≤±0.02 mm;

Efficient iteration: rapid trial production cycle is 7–10 days, design optimization response is ≤48 hours;

Customized support: supports different industry certifications (ISO 13485, IATF 16949, etc.) and special material requirements;

Experience accumulation: 10+ years of mold development experience, with a total of more than 500 projects delivered, covering automotive, medical, electronics and other fields.

Contact us now to start the efficient journey of plastic parts from concept to mass production, and let the professional plastic injection mold design team escort you!

Contact information:

Tel: +8615602392025

Email: longterm@longterm-mold.com

Official website: www.longterm-mold.com