The moldIndustry is undergoing a radical transformation as advanced R & D service breakthroughs redefine plastic injection mold design. Where traditional injection mould tool design relied on manual methods, cutting-edge R and D service innovations now drive industrial development and design through data-powered solutions. These advances are revolutionizing plastic molding design where precision dictates production success.

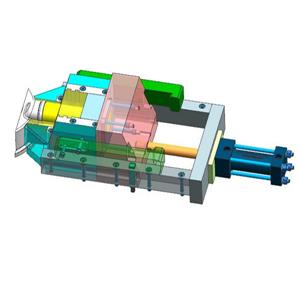

Modern R and D service teams have transformed simulation capabilities for injection mould tool design. Advanced Finite Element Analysis now predicts stress distribution with 95% accuracy during the digital phase. For plastic injection mold design specialists, this R and D service-validated approach identifies warpage risks before tooling begins. Leading moldIndustry firms report 40-60% faster design cycles through such R and D service-developed simulation methods for plastic molding design.

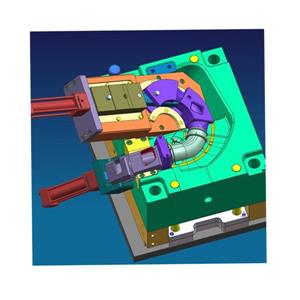

Automation powered by R & D service initiatives has particularly impacted plastic injection mold design workflows. AI systems can generate hundreds of gate location options for injection mould tool design in minutes - a task that previously required days of R and D service testing. This extends to cooling optimization in plastic molding design, where R and D service-created algorithms balance thermal and structural needs. One major provider's R and D service demonstrated automated plastic injection mold design cutting cooling system development from three weeks to 72 hours.

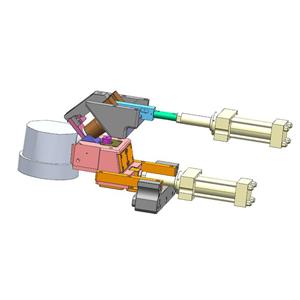

Additive manufacturing, accelerated by R and D service programs, has revolutionized injection mould tool design. Complex conformal cooling channels impossible with traditional methods are now standard in advanced plastic molding design. Through dedicated R and D service efforts, moldIndustry leaders use metal 3D printing to produce inserts improving cycle times by 30-40%. Numerous R and D service divisions have fully integrated additive methods into plastic injection mold design workflows.

Data integration, a key R & D service focus, has dramatically advanced injection mould tool design. Cloud-based systems aggregate decades of plastic molding design knowledge into searchable databases developed through continuous R and D service improvements. When starting new plastic injection mold design projects, engineers access R and D service-compiled historical solutions, accelerating problem-solving. One moldIndustry leader reported their R and D service team cut new tool development time by 55% using such systems.

Collaborative R and D service approaches have transformed plastic molding design. Modern industrial development and design platforms enable real-time teamwork between designers, material scientists, and production staff - a methodology perfected through extensive R and D service testing. This proves invaluable for complex plastic injection mold design projects balancing multiple requirements. Progressive R and D service providers now build these collaborative tools directly into moldIndustry solutions.

Material science advancements driven by intensive R & D service work are expanding plastic molding design possibilities. New high-performance steels and coatings allow injection mould tool design engineers to create tools lasting millions of cycles - a direct result of persistent R and D service efforts. These innovations, combined with advanced plastic injection mold design software developed through R and D service initiatives, enable increasingly complex geometries. Dedicated R and D service teams continuously test novel material combinations to push industrial development and design boundaries.

Sustainability-focused R and D service work is reshaping injection mould tool design. Energy-efficient plastic molding design now minimizes cycle times while maximizing quality - an approach refined through rigorous R and D service analysis. Many plastic injection mold design specialists use R and D service-validated simulation to optimize runner systems, reducing material waste by 15-25%. Forward-thinking moldIndustry R and D service providers view sustainable industrial development and design as both ecological necessity and competitive edge.

The future of plastic molding design lies in converging these R & D service-proven technologies. Emerging digital twin systems connect production data back to injection mould tool design, creating improvement loops perfected through ongoing R and D service work. As AI matures, plastic injection mold design will become more automated, with systems proposing solutions based on R and D service-established parameters. Innovative moldIndustry R and D service teams are already prototyping self-optimizing industrial development and design platforms that learn from every project.

For manufacturers, these R & D service-driven advances in plastic molding design deliver real benefits. Faster injection mould tool design means quicker market entry. More accurate plastic injection mold design reduces costly modifications. Advanced industrial development and design methods yield longer-lasting, better-performing molds. As the moldIndustry evolves, companies leveraging these R and D service-validated technologies will gain significant advantages in competitive markets.

The future of injection mould tool design lies in seamlessly integrating these R & D service-developed technologies. Tomorrow's plastic molding design specialists will work with unified systems combining simulation, automation, additive manufacturing, and analytics - all refined through continuous R and D service efforts. Plastic injection mold design will become more about guiding intelligent systems than manual creation. For the moldIndustry, this R and D service-powered transformation presents both challenges and opportunities to redefine manufacturing excellence.