High-Quality Plastic Injection Molding: Precision Engineering for Demanding Applications

Plastic Injection molded parts form the backbone of modern manufacturing, enabling mass production of intricate components—from smartphone casings to automotive engine blocks. The molding of plastic parts is far more than a basic shaping process; it’s a symphony of material science, precision tooling, and advanced engineering that ensures durability, aesthetics, and functionality.

1. Material Selection: The Foundation of Superior Injection-Molded Parts

The performance of technical parts hinges on raw material properties: strength, heat resistance, and chemical stability. Thermoplastic Injection processes demand rigorous testing to certify materials meet industry standards. Key considerations include:

Plastic Injection molded parts often use engineering-grade thermoplastics for high-impact applications.

Molding of plastic parts requires uniformity; suppliers audit materials to prevent defects like warping or degradation.

For technical parts, third-party certifications ensure repeatable quality in critical sectors.

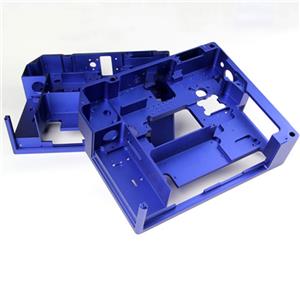

2. Advanced Mold Design: Precision Tooling for Complex Geometries

The mold is the heart of Injection-molded parts production. Cutting-edge CAD/CAM systems design molds with micron-level tolerances, while durable materials (hardened steel alloys) withstand high-pressure Thermoplastic Injection cycles. Highlights:

Plastic Injection molded parts rely on molds with cooling channels to minimize shrinkage.

Molding of plastic parts for technical parts (e.g., gears, connectors) demands multi-cavity molds for batch consistency.

Proper maintenance extends mold life, reducing downtime in Thermoplastic Injection workflows.

3. The Injection Process: Balancing Speed and Accuracy

Producing Injection-molded parts requires precise control over parameters:

Plastic Injection molded parts must achieve even melt flow to fill cavities without air traps.

Thermoplastic Injection machines adjust pressure/temperature dynamically for thin-walled technical parts.

Automation monitors molding of plastic parts, reducing human error in high-volume runs.

4. Post-Processing and Quality Assurance

After ejection, Injection-molded parts undergo finishing (deburring, surface texturing) and rigorous QA:

Technical parts are inspected dimensionally and tested under stress.

Statistical Process Control (SPC) tracks deviations in Thermoplastic Injection cycles, preempting defects.

Plastic Injection molded parts destined for assembly are validated for fit and function.

5. Cost vs. Value: Why Precision Matters

While molding of plastic parts in commodity plastics is cost-effective, technical parts justify premium Thermoplastic Injection processes through:

Longer tool life for complex Injection-molded parts.

Reduced waste via optimized Plastic Injection molded parts cycles.

Conclusion

From everyday items to mission-critical technical parts, Plastic Injection molded parts exemplify manufacturing excellence. The molding of plastic parts via Thermoplastic Injection blends artistry with engineering—delivering Injection-molded parts that meet exacting standards for performance, aesthetics, and reliability.