02-14/2025

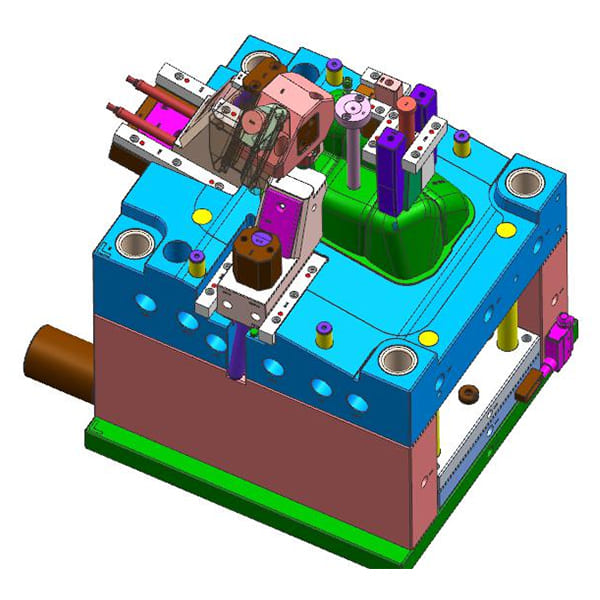

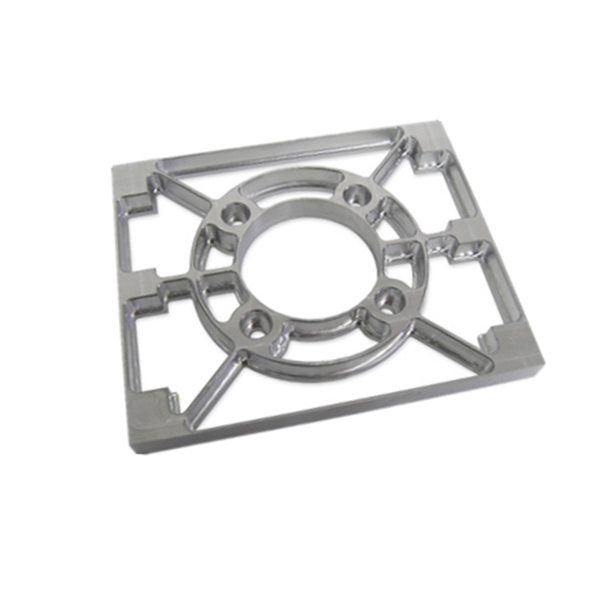

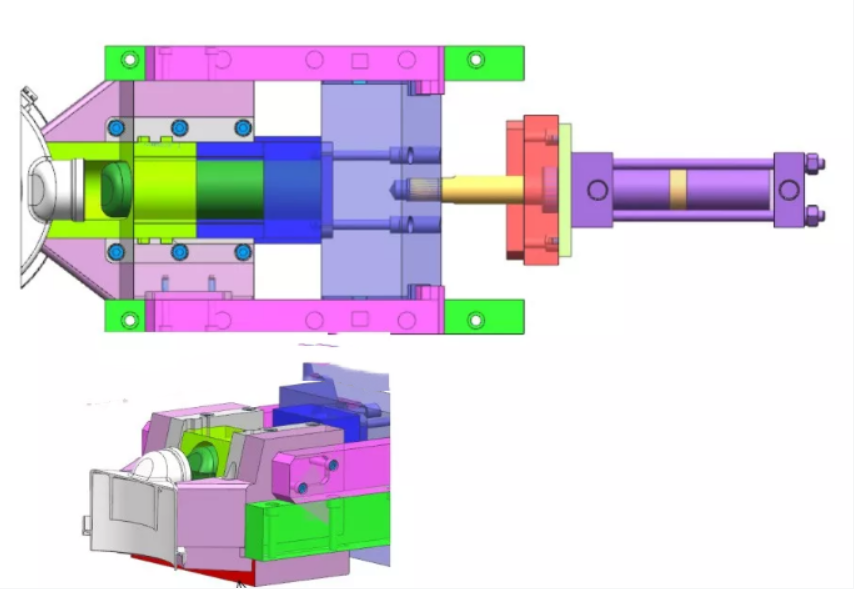

The relentless march of technological advancement demands ever-smaller, faster, and more sophisticated electronic components. This miniaturization, however, presents significant challenges in manufacturing. Creating the intricate molds required for producing these complex electronic parts necessitates a high degree of precision and specialized engineering solutions. This article delves into the critical role of precision engineering in crafting the molds that shape the future of electronics. The demand for seamless integration, high functionality, and superior reliability in consumer electronics, medical devices, and automotive systems fuels the need for innovative and precise mold-making techniques. Failure to meet these exacting standards can result in costly production delays, faulty components, and compromised product performance. Therefore, understanding the intricacies of precision engineering solutions for complex electronic molds is paramount for manufacturers striving for excellence.