09-22/2025

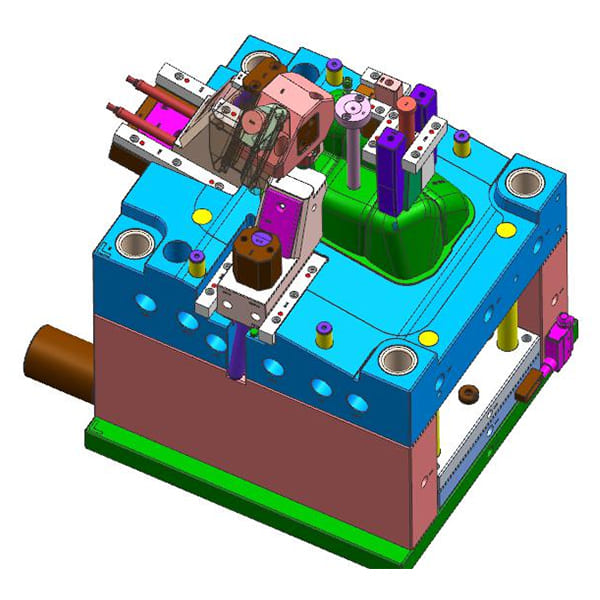

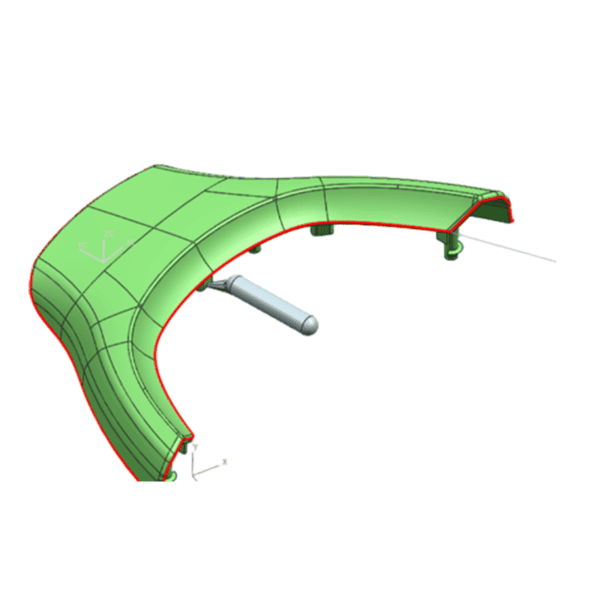

Low-yield production tools build a "fast-provincial-flexible" integrated development model through rapid proofing, prototype molds and low-yield CNC processing, significantly shortening the product development cycle, reducing early investment, and improving design iteration efficiency, helping new products to quickly verify and market introduction.