"One Stop Service" typically refers to a comprehensive service provided by a company or entity that specializes in mold manufacturing. This service encompasses the entire process of mold creation, from design to production. Here's an overview of Longterm Mold One stop service might entail:

1.Design: The service provider may offer design services, either in-house or through partnerships with design firms, to help clients develop mold designs tailored to their specific needs and requirements.

2.Prototyping: Once the design is finalized, the service may include prototyping services to create a physical representation of the mold before full-scale production begins. Prototyping allows for testing and refinement of the design.

3.Mold Analysis:Our plastic engineering knowledge and tooling experience combined with the latest technological advancements provide you with the most cost-effective and efficient service processes and solutions. Our Plastic Engineering & Technical Services team is a recognized leader in providing analytical services in mold-filling, mold cooling, shrink & warp analysis, gas assist analysis, injection compression, co-injection and more. To achieve the most optimal manufacturing solution, we recommend the moldflow simulation process for multiple gate parts, family tooling, multicavity and imbalanced molds. Save time and money by conducting a moldflow analysis during the design process.

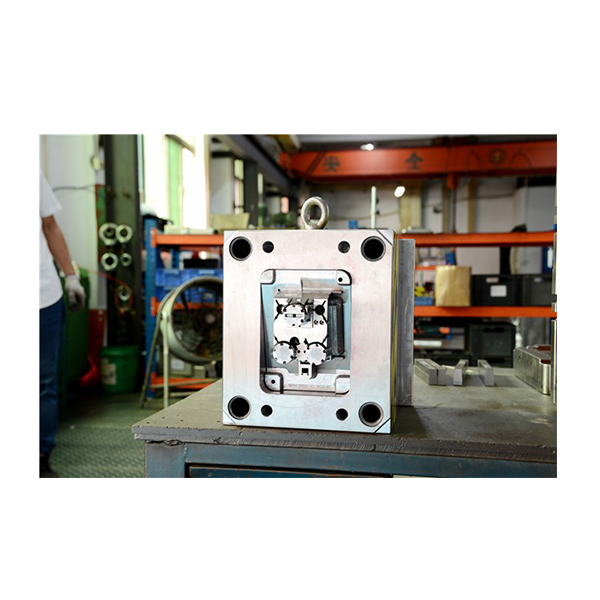

3.Tooling: This involves the fabrication of the tools necessary for the mold manufacturing process. It may include CNC machining, EDM (Electrical Discharge Machining), or other techniques to create the mold components.

4.Mold Manufacturing: The core service is the manufacturing of the mold itself. This includes assembling the various components, ensuring precision and accuracy according to the design specifications.

5.Quality Assurance: A comprehensive mold one-stop service will typically include quality assurance measures throughout the manufacturing process. This may involve inspections, testing, and validation to ensure that the mold meets the required standards and specifications.

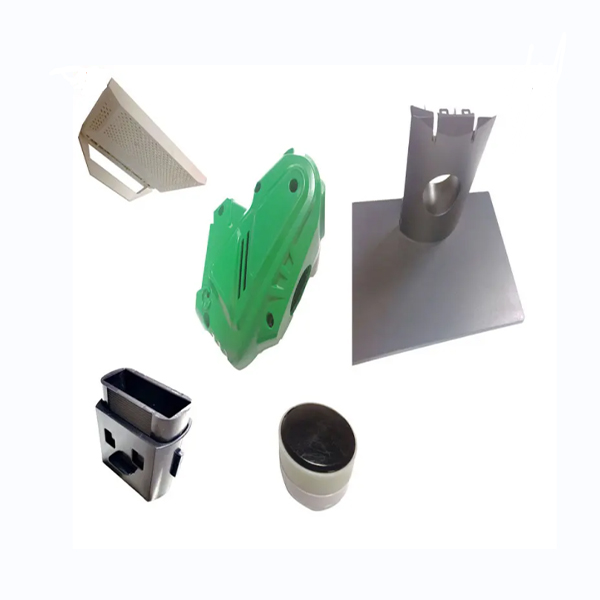

6.Post-Production Support: After the mold is manufactured, the service provider may offer additional support such as Automation equipment,parts assembly,painting,jigs fixture...

7.Logistics and Delivery: Finally, the service may also include logistics support to ensure the timely delivery of the mold to the client's location.

Longterm mold not only provides injection mold manufacture, but also provides relevant services such as rubber silicone parts,stamping,die casting,machining parts,blow moulding tools...