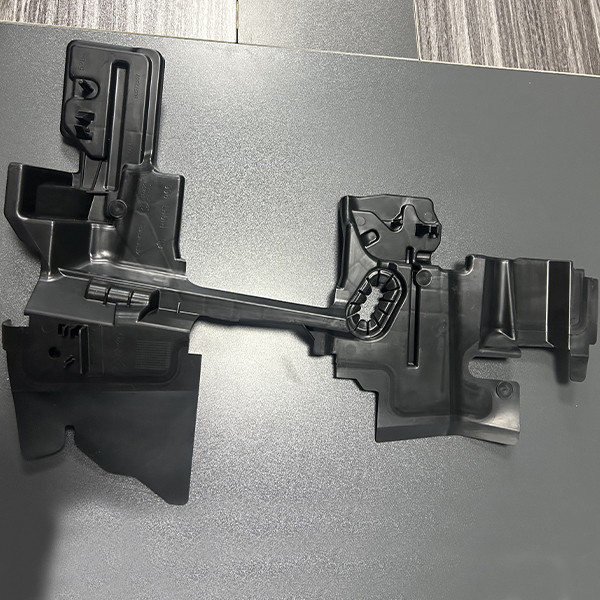

1.The two female shapes are different and the products must be formed separately, but the two male shapes must be exactly the same.

2.The molds on the front and back of the mold must be rotated 180 ° from the center and then aligned.

3.The total thickness of the front mold panel and A board must be 170mm or more. It is necessary to carefully check the maximum mold thickness, minimum mold thickness, KO hole distance, etc.

4.The nozzle of the plate mold should be designed to release the mold automatically.

5.When designing a master mold for the second injection, some avoidance can be designed so that the second master mold does not damage the bond position of the first molded product. However, the strength of each seal position should be carefully considered (that is, in injection molding, can the plastic deform at high injection pressures and crack in the second injection?).

6.For injection molding, you can slightly increase the size of the first injection molded product and press firmly with another male mold during the second molding to achieve a sealing effect.

7.Watch out if the plastic flow impacts the first formed product and deforms the position of the adhesive during the second injection.

8.Before closing the A and B boards, pay attention to whether the front mold slider or tilted top is reset first and the product is crushed.

9.The arrangement of the two female and male water transports is as sufficient and balanced as possible.

10.At 99%, the soft rubber is easily deformed, so the hard rubber part of the injection product is injected first, and then the soft rubber part of the injection product is injected.