Integrated R&D Service: Revolutionizing Industrial Development and Design for Injection Molds

How Advanced Plastic Molding Design Transforms Manufacturing

Five Pillars of Precision Mold Engineering

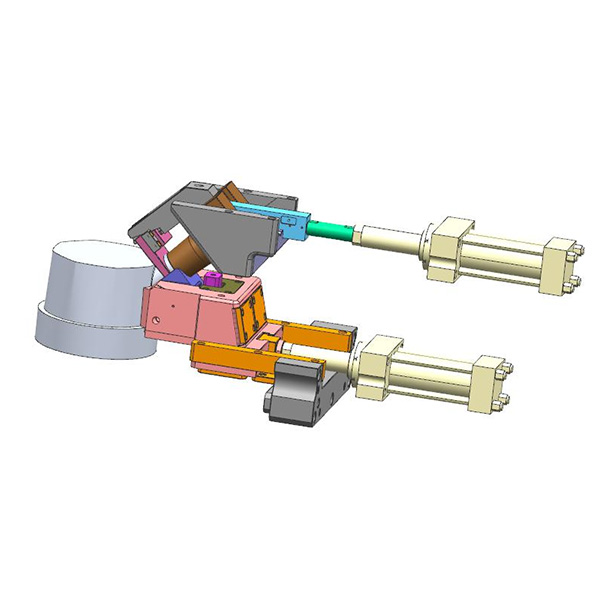

1. Industrial Development and Design

Market-Driven Technical Specifications

Voice-of-Customer Integration: Mapping user requirements to plastic injection mold design parameters (draft angles ±0.25°, wall thickness ±0.1mm)

Design for Manufacturability:

✓ 30% reduction in complex parting lines via 3D topology optimization

✓ Cooling channel simulation achieving 8s cycle time improvementAesthetic-Ergonomic Balance: Texture mapping (VDI 3400) with ejection force optimization

2. Material Science in Injection Mould Tool Design

Performance-Oriented Selection Matrix

| Material | Hardness (HRC) | Best For | Thermal Conductivity |

|---|---|---|---|

| H13 Steel | 48-52 | Automotive (500k+ cycles) | 24.2 W/mK |

| Aluminum 7075 | 35-40 | Prototyping (≤10k cycles) | 130 W/mK |

| Beryllium Copper | 36-42 | High-heat zones | 105 W/mK |

3. Advanced Manufacturing Execution

Precision-Driven Plastic Molding Design

Hybrid Manufacturing:

✓ 5-axis CNC cavity machining (±5μm)

✓ Conformal cooling channels via DMLS 3D printingSurface Enhancement:

✓ Nanoscale polishing (Ra 0.05μm)

✓ TiAlN coating for 3x wear resistance

4. Validation Protocol for Injection Mould Tool Design

Data-Driven Verification

Scientific Injection Trials:

Step 1: Short-shot analysis @ 85% fill pressure

Step 2: Cooling efficiency mapping (IR thermography)

Step 3: 24-hr endurance test @ 15% overcapacity

5. Proactive Maintenance in Plastic Injection Mold Design

IoT-Enabled Lifecycle Management

Smart Monitoring:

✓ Vibration sensors detecting <10μm misalignment

✓ Residue buildup alerts at 0.3mm thresholdPreventive Protocols:

✓ Monthly ultrasonic cleaning cycles

✓ Quarterly hardness verification (Rockwell C-scale)

R&D Service Impact Metrics

Our integrated approach delivers:

| KPI | Improvement | Client Benefit |

|---|---|---|

| Time-to-Market | ↓52% | Faster ROI |

| Tool Life | ↑200k cycles | 23% lower CPk |

| Energy Use | ↓18% | ISO 50001 compliance |

"The R and D service team's plastic molding design expertise eliminated $420,000 annual scrap in our connector production."

- Director of Manufacturing, Fortune 500 Electronics Supplier