In the brilliant landscape of modern manufacturing, the plastic injection molding industry is undoubtedly a shining star, emitting unique brilliance and profoundly influencing all aspects of people's lives and industrial development. It transforms granular plastic raw materials into a wide range of plastic products through exquisite processes and advanced equipment. From small daily items to key components in industrial production, plastic injection molded products are everywhere—all relying on high-quality plastic injection mold and sophisticated Mold Manufacturing technologies.

I. Industry Development History and Current Situation

The plastic injection molding industry has a long development history, dating back to the 19th century. At that time, injection molding technology was in its infancy, but its application scope was limited due to backward technology and materials. As time progressed, in the 1940s, the birth of screw injection machines and the improvement of plastic material performance became important turning points in the industry's development. These advancements propelled injection molding technology forward significantly, enabling it to gain a firm foothold in the industrial sector. In the following decades, injection molding machines continued to be upgraded, with automation levels significantly improved, production efficiency and product quality greatly enhanced, and the industry's application scope continuously expanded—driven by innovations in injection mold design and manufacturing.

Today, the plastic injection molding industry has matured, with continuous technological innovations. Cutting-edge technologies such as hot runner technology, gas-assisted injection molding, and multi-component injection molding have emerged one after another, greatly improving the performance, production efficiency, and quality stability of injection molded products. According to relevant data, China occupies a leading position in global injection molding production and consumption, accounting for over 50% of global output in 2022. Domestically, the market scale of the injection molding industry continues to expand: the market scale of China's injection molding machine industry reached 25.21 billion yuan in 2020 and grew to 26.304 billion yuan in 2021. In terms of industrial layout, East China, South China, and Central China have become industry clusters, forming a number of influential industrial clusters with complete Mold Manufacturing chains.

II. Analysis of Industry Advantages

(1) High Production Efficiency

One of the prominent advantages of the plastic injection molding process is its ability to achieve rapid prototyping, enabling mass production of products with consistent specifications in a short period. Modern injection molding machines have increasingly high automation levels, and when combined with precision plastic injection mold, they can easily achieve 24/7 continuous production, effectively ensuring the on-time delivery of large-scale orders. For example, in the electronic and electrical industry, the production of products such as mobile phone cases and TV remote controls relies on the efficiency of injection molding processes to meet the huge market demand for product quantity—all supported by high-precision injection mold that ensures stable production.

(2) High Precision and Complex Shape Molding

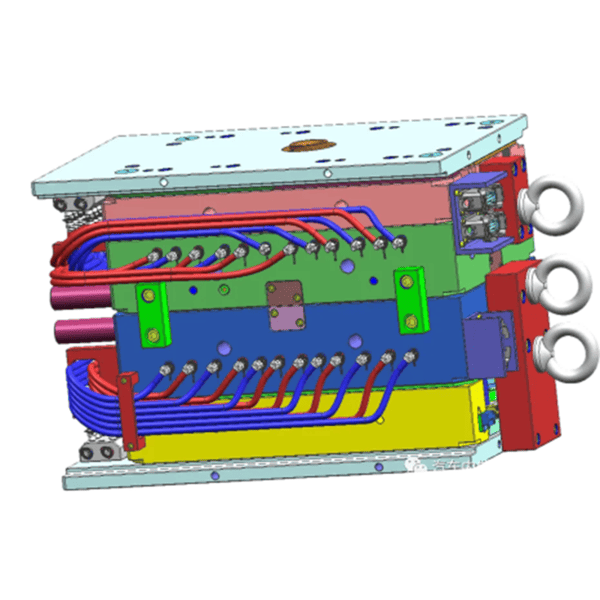

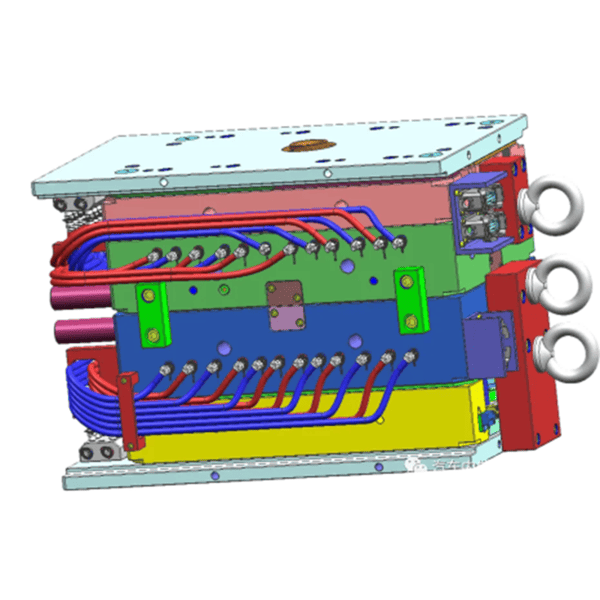

Relying on advanced Mold Manufacturing technology and precision injection molding equipment, the plastic injection molding process excels in molding high-precision and complex-shaped products. Whether it is components with fine internal structures or products with unique appearance designs, the injection molding process can accurately reproduce them, providing a broad space for creativity and realization in product design. Taking some components in the automotive industry as an example, such as complex plastic parts around the engine, the injection molding process—supported by customized plastic injection mold—ensures perfect molding of dimensional accuracy and complex structures.

(3) Significant Cost-Effectiveness

From the perspective of large-scale production, the unit cost of plastic injection molding is relatively low. Through continuous optimization of injection mold design and production processes, raw material waste can be effectively reduced, and production costs can be lowered. Although the initial investment in plastic injection mold is relatively high, the cost can be effectively amortized during long-term production, bringing considerable economic benefits to enterprises in the long run. For example, in the production of daily necessities, the large-scale production of plastic tableware achieves low-cost and high-efficiency manufacturing through injection molding processes, with optimized Mold Manufacturing further controlling costs.

III. Diversified Application Fields

(1) Automotive Industry

The plastic injection molding process is widely used in the automotive manufacturing field. From exterior body parts such as bumpers and rearview mirror housings, to interior parts such as instrument panels and seat frames, and even engine components and car lights—all rely on injection molded products. With the rise of electric vehicles and intelligent connected vehicles, the automotive industry has put forward more stringent requirements for the lightweight, intelligence, and personalization of injection molded parts. To meet these needs, the injection molding industry has actively innovated, using carbon fiber-reinforced plastics and long glass fiber PP materials to manufacture lighter and stronger automotive parts—all based on advanced Mold Manufacturing technology that adapts to new material properties.

(2) Electronic and Electrical Industry

The electronic industry is one of the important application fields of the plastic injection molding industry. Most electronic and electrical products such as mobile phone cases, TV casings, home appliance housings, connectors, and battery casings are produced using injection molding processes. As electronic products develop towards thinness, lightness, and functional integration, the precision of plastic injection mold and the production efficiency of injection molding processes have become key influencing factors. At the same time, consumers have increasingly high requirements for the appearance design of electronic products, and the innovative upgrading of injection molding technology—including the application of injection mold printing for personalized surface effects—provides strong support for achieving unique appearance results. For example, some high-end mobile phone casings achieve exquisite appearance texture and lightweight design through special injection molding processes, with customized injection mold ensuring consistent quality.

(3) Medical Industry

The medical field has a wide range of important demands for plastic injection molded products. Disposable syringes, breathing masks, IVD consumables, and medical device housings all need to be produced using injection molding processes. The medical industry has extremely high requirements for the biocompatibility, non-toxicity, hygiene, and precision of injection molded products, which has also promoted the continuous improvement of technology in the injection molding industry. For example, the development of micro-injection molding technology has made it possible to produce high-precision small medical components—supported by micro-precision Mold Manufacturing and even 3D printing services for prototype mold development, providing technical support for the manufacturing of personalized medical equipment.

(4) Daily Consumer Goods Category

In daily life, plastic injection molded products are everywhere. Consumer goods such as plastic household items, daily plastic products, toys, food packaging, and stationery are mostly produced using injection molding processes. These products require low production costs, short production cycles, and high customization levels, and the injection molding process can perfectly meet these needs, bringing convenience and a variety of choices to people's lives. For example, a variety of cute-looking plastic toys achieve large-scale production and diversified designs through injection molding processes, with plastic injection mold customized according to toy shapes to ensure vivid details.

IV. Insights into Cutting-Edge Development Trends

(1) Intelligent and Automated Upgrading

Currently, injection molding machines equipped with AI algorithms and IoT technology are gradually becoming popular. These injection molding machines can realize real-time data monitoring, fault prediction, and process optimization. The application of collaborative robots and AGVs (Automated Guided Vehicles) is also accelerating, helping to build 24/7 unmanned workshops to adapt to the demand for small-batch and multi-variety orders. Through intelligent systems, various parameters in the production process can be accurately controlled, product quality is more stable, and production efficiency is significantly improved. Some advanced injection molding enterprises have realized a high degree of automation in their production workshops: from raw material feeding and injection molding to product sorting, all are completed by intelligent equipment in collaboration—with injection mold status monitored in real time to ensure continuous production.

(2) In-Depth Application of Digital Twin Technology

Digital twin technology optimizes Mold Manufacturing and production processes through virtual simulation, which can significantly shorten the product development cycle and reduce trial-and-error costs. For example, using metal 3D printing services to produce conformal cooling molds can reduce cooling time by more than 30%, greatly improving production efficiency. By establishing virtual models, the production process can be simulated in advance, potential problems can be identified and solved in a timely manner, and the smooth progress of actual production can be ensured. Some large injection molding enterprises have introduced digital twin technology: in the product development stage, they optimize plastic injection mold design and injection parameters through virtual models, effectively reducing debugging time and scrap rates in actual production.

(3) Green and Environmental Protection Led Development

Against the background of the global "plastic ban" (such as the promotion of the EU SUP Directive), the demand for bio-based and degradable plastics such as PLA and PHA has surged. Injection molding enterprises have increased R&D investment to develop processes adapted to new materials. At the same time, the requirement of consumer brands to increase the proportion of recycled plastics has also prompted the injection molding industry to actively establish a closed-loop recycling system. In addition, replacing traditional hydraulic machines with electric injection molding machines can reduce energy consumption by more than 50%, which is more in line with the requirements of low-carbon production and promotes the accelerated transformation of the injection molding industry towards green and environmental protection. Some injection molding enterprises have successfully developed injection molded products based on degradable plastics, and actively adopted environmental protection processes in production—with Mold Manufacturing also optimized to reduce energy consumption and waste emissions.

(4) Industrial Transfer and Supply Chain Reconstruction

Labor-intensive injection molding links tend to shift to Southeast Asia, India, and other regions. Domestic enterprises can seize the market through joint ventures or technology export. European and American enterprises tend to purchase locally to shorten the supply chain, which increases the demand for injection molding capacity in Mexico and Eastern Europe. The "Belt and Road" Initiative has brought demand for plastic building materials in infrastructure projects in emerging markets such as Africa and the Middle East to the injection molding industry. The injection molding industry is actively adapting to these changes and reshaping the supply chain structure. Some domestic injection molding enterprises have invested in building factories in Southeast Asia, using local labor advantages and policy preferences to expand overseas markets; at the same time, some enterprises have seized the opportunity of the "Belt and Road" Initiative to provide high-quality injection molded products for infrastructure construction in emerging markets—supported by localized Mold Manufacturing and after-sales services.

The plastic injection molding industry will continue to grow and develop in the future, relying on its continuous innovative technology, increasingly expanded application fields, and active response to trends such as environmental protection. Whether it is meeting the demand for high-performance products in various industries or providing convenience for people's daily lives, the plastic injection molding industry will play an even more important role and become a key force driving the development of modern manufacturing. If you have any needs for plastic injection molded products—whether it is customized plastic injection mold, advanced Mold Manufacturing services, or support for injection mold printing and 3D printing services—please feel free to contact us. We will provide you with customized and satisfactory injection molding solutions with professional technology and high-quality services.