From Concept to Completion: Precision Manufacturing Process

Our comprehensive approach begins with expert products design and development, where our engineering team transforms ideas into manufacturable solutions. The 3D part design phase utilizes cutting-edge software to create digital prototypes, ensuring optimal functionality before physical production begins. This part development process typically reduces time-to-market by 30-40% compared to conventional methods.

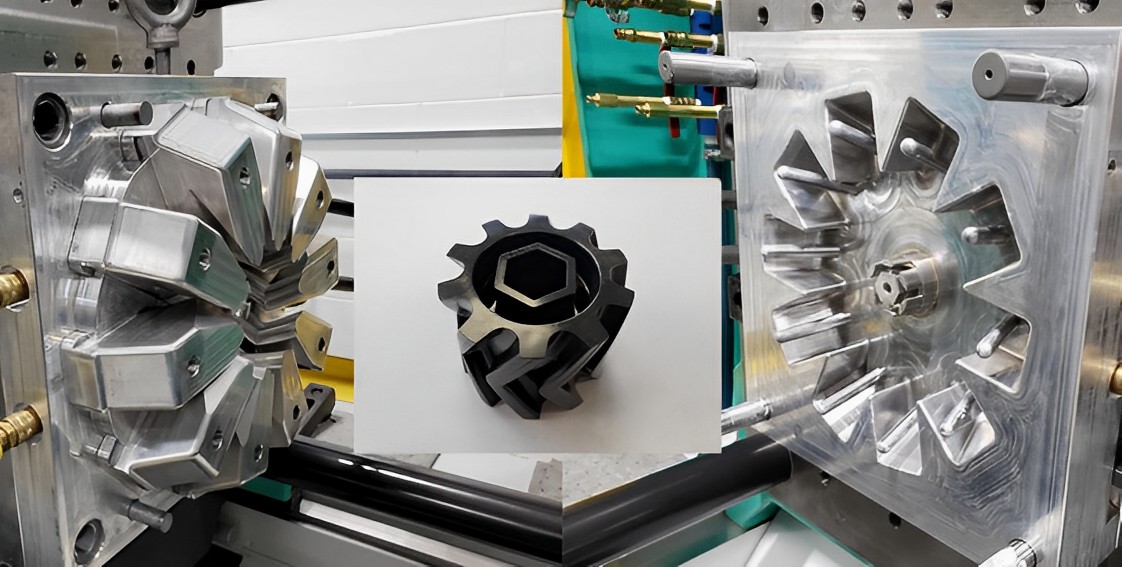

Advanced Mold Creation

Following successful Part CAD design validation, our skilled craftsmen begin mold fabrication using premium materials:

Grade P20 steel for high-volume mechanical products design and development projects

Aluminum 6061 for rapid prototyping molds

Custom alloys for specialized products design and development requirements

Precision Manufacturing Technologies

We employ state-of-the-art equipment to execute your 3D part design:

5-axis CNC machining for complex part development geometries

Micro-milling (±0.005mm tolerance) for precision Part CAD design components

EDM machining for intricate mechanical products design and development features

High-Volume Production Capabilities

Our manufacturing expertise covers all major processes:

Injection molding for mass production of products design and development components

Blow molding for hollow 3D part design applications

Compression molding for high-strength part development requirements

Quality Assurance Protocol

Every Part CAD design undergoes rigorous testing:

Dimensional verification of mechanical products design and development components

Material testing for products design and development specifications

Functional testing of 3D part design prototypes

Stress analysis for part development validation

Technical Specifications

Our Part CAD design capabilities include:

Minimum wall thickness: 0.5mm for mechanical product design and development

Maximum part size: 1500mm × 800mm × 500mm for product design and development

Surface finishes from VDI 12 to mirror polish for 3D part design

Tolerances to ISO 2768-fine for precision part development

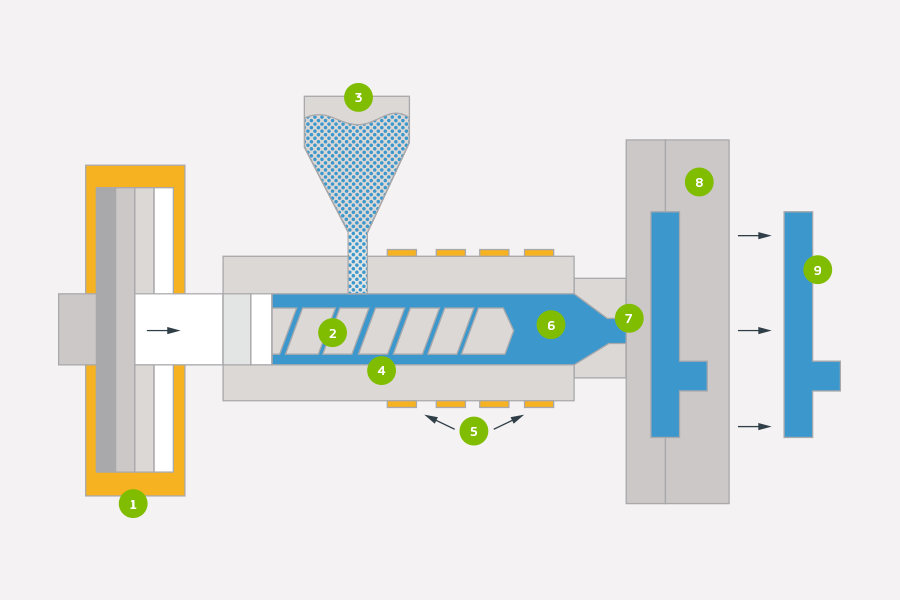

Streamlined Production Workflow

The complete process from Part CAD design to delivery:

Initial mechanical products design and development consultation (2-5 days)

Product design and development refinement (1-2 weeks)

3D part design prototyping (3-7 days)

Part development tooling creation (2-4 weeks)

Mass production launch (ongoing)

Why Choose Our Services

15+ years experience in mechanical product design and development

ISO 9001 certified products design and development processes

40% faster 3D part design turnaround than industry average

99.8% quality approval rate for part development projects

Competitive pricing for Part CAD design services

Conclusion

Our integrated approach combining expert mechanical product design and development with advanced manufacturing technologies ensures:

Flawless execution of your product design and development vision

Precision realization of 3D part design concepts

Efficient part development processes

Accurate Part CAD design translation to physical products

Cost-effective mechanical product design and development solutions