Analysis of the entire process of precision mold development: key technological breakthroughs from design to mass production

【Introduction】

Against the backdrop of global manufacturing upgrading, mold development, as the core link of industrial production, is promoting the rapid transformation of products from concept to mass production. This article will thoroughly analyze the five key stages of mold development and reveal how industrial design, materials science and precision manufacturing can collaborate on creating efficient mold systems.

1. Industrial design and development: from market demand to 3D model

The first step in mold development begins with Industrial Development and Design, which focuses on the precise connection between product functions and production needs:

Demand analysis: Determine mold parameters based on product specifications, user feedback and expected output;

3D modeling optimization: designers convert product models into structures that meet the requirements of Plastic Injection Mold Design to ensure that details such as mold release slope, wall thickness and parting lines can be implemented;

Manufacturingability assessment: Balancing aesthetics and production efficiency to avoid late-production bottlenecks.

2. Material selection: the key to determining mold life and performance

In Injection Mould Tool Design, the material directly relates to cost and durability:

Common materials: High-strength alloy steel (such as P20, H13) is suitable for mass production, while aluminum molds are used for rapid prototyping verification;

Performance considerations: high temperature resistance, chemical corrosion resistance and adaptability of complex parts;

Heat treatment process: improve hardness through quenching, tempering and other processes to reduce production deformation.

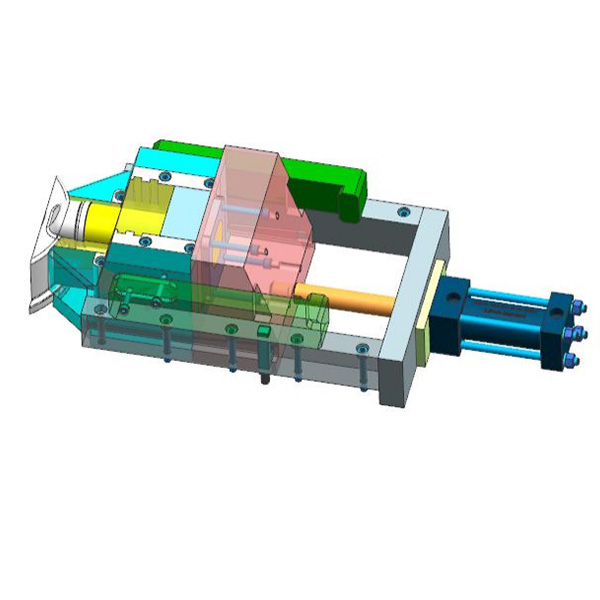

3. Precision manufacturing: CNC and EDM technology achieve micron-level accuracy

The mold manufacturing stage relies on high-precision processing technology:

CNC machining (CNC): creates core mold core, cavity and runner system, with tolerances controlled within ±0.01mm;

Electric discharge machining (EDM): handles complex geometric shapes to ensure surface finish;

Cooling system optimization: Embed high-efficiency cooling channels through plastic injection mold design to shorten production cycles.

4. Test model verification: practical testing and parameter tuning

Before the mold is put into production, it must pass strict verification:

Mod test stage: detect part size and surface defects (such as shrinkage marks and flashes);

Process debugging: Adjust injection pressure, temperature and cooling time to solve the problem of warping or insufficient filling;

Mass production meets standards: Ensure that the mold meets industrial design goals and achieves a yield rate of more than 95%.

5. Maintenance and Upgrade: Compulsory courses for extending mold life

Regular maintenance is the core of ensuring the economical design of injection mold tool:

Cleaning and rust prevention: remove residual resin to avoid corrosion;

Replace wear parts: Check regularly for wearable parts such as thimbles, guide columns, etc.;

Iterative upgrade: adapt to product design changes and integrate into the latest industrial trends.

【Conclusion】

From concept design to mass production and maintenance, mold development has become an engine of efficient innovation in the manufacturing industry by integrating three pillars: industrial design and development, injection mold tool design and plastic injection mold design. With the penetration of intelligent technology, mold development will further evolve towards digitalization and rapid response in the future.