I. Cause Analysis of Cracks in Injection - Molded Plastic Parts and Products

- Processing aspects in Plastic Injection Molding

Excessive processing pressure, too high speed, over - filling, too long injection and holding time will all cause excessive internal stress and lead to cracking in plastic parts. In the plastic injection mold design, proper consideration should be given to how these parameters interact.

Adjusting the mold - opening speed and pressure is crucial to prevent the plastic parts from being strongly pulled during demolding and thus cracking. This is an important aspect of the overall plastic injection mold design.

Appropriately increasing the mold temperature in plastic injection mold manufacturing makes the plastic parts easier to demold, and appropriately lowering the material temperature prevents decomposition.

Preventing cracking caused by the reduction of mechanical strength due to weld lines and plastic degradation is essential in plastic products production.

Using demolding agents properly and regularly removing substances such as aerosol material residues on the mold surface are necessary steps in plastic injection molding.

Relieving the residual stress of the plastic parts by immediate annealing heat treatment after molding can reduce the generation of cracks.

- Mold aspects in Mold Manufacturing

The ejection should be balanced in the plastic injection mold. For example, the number and cross - sectional area of the ejector pins should be sufficient, the draft angle should be enough, the cavity surface should be smooth enough to avoid sticking to the front mold, and the core surface should ensure that deep rib positions have sufficient draft angles. This can prevent cracking caused by the concentration of residual stress during ejection due to external forces.

The structure of the plastic parts should not be too thin. Arc transitions should be used as much as possible in transition parts to avoid stress concentration caused by sharp corners. Good plastic injection mold design takes these structural factors into account.

Using metal inserts as little as possible in automotive mold or other plastic injection molds can prevent increased internal stress due to different shrinkage rates between the insert and the plastic part, or pre - heating the metal inserts.

For deep - bottom plastic parts, appropriate demolding air - inlet channels should be set to prevent the formation of vacuum negative pressure in the plastic injection mold.

The main runner in the plastic injection mold should be large enough so that the gate material can be demolded before it is completely solidified, which is conducive to demolding.

The joint between the sprue bushing and the nozzle in the plastic injection mold should prevent the dragging of cold - hardened material, which may cause the plastic part to stick to the fixed mold (not applicable to hot - runner systems).

- Material aspects in Plastic Products Production

Too high a content of recycled material results in too low strength of plastic parts. This can be a significant factor in plastic products production.

Excessive humidity causes some plastics to chemically react with water vapor, reducing strength and resulting in ejection cracking in plastic parts.

The material itself being not suitable for the processing environment or having poor quality and being contaminated can all cause cracking in plastic products.

- Machine aspects in Plastic Parts Production

The plasticizing capacity of the injection molding machine used in plastic parts production should be appropriate. If it is too small, the plasticizing is insufficient and the materials cannot be fully mixed, making the plastic parts brittle. If it is too large, the material may degrade.

II. Cause Analysis of Bubbles in Injection - Molded Plastic Parts

Increasing injection energy: pressure, speed, time and material quantity, and increasing back pressure to make the mold filling full is important in plastic injection molding.

Increasing the material temperature to make the flow smooth, lowering the material temperature to reduce shrinkage, and appropriately increasing the mold temperature, especially the local mold temperature at the position where the vacuum bubble is formed are key steps in dealing with bubbles in plastic parts.

Setting the gate at the thick part of the plastic part, improving the flow conditions of the nozzle, runner and gate, and reducing pressure consumption are necessary for good plastic injection mold design to avoid bubble formation.

Ensuring smooth exhaust at the mold parting surface and improving the exhaust condition at key positions of the plastic injection mold can prevent bubbles in plastic parts.

III. Cause Analysis of Warpage and Deformation in Injection - Molded Plastic Parts

- Mold aspects in Mold Manufacturing

When designing the product structure of plastic parts, the wall thickness of the plastic part should be as uniform as possible. This is a basic principle in plastic injection mold design.

The design of the cooling system in the plastic injection mold should make the temperature of each part of the mold cavity uniform. The gating system should make the material flow symmetrical to avoid warpage caused by different flow directions and shrinkage rates. Appropriately thickening the sub - runner and main runner near the difficult - to - mold positions to eliminate the density difference, pressure difference and temperature difference in the cavity as much as possible is important in plastic injection mold design.

The transition areas and corners of the plastic part's wall thickness should be smooth enough, and it should have good demoldability, such as increasing the draft angle, improving the mold surface polishing, and keeping the ejection system balanced.

Good exhaust in the plastic injection mold is necessary to prevent warpage.

Increasing the wall thickness of the plastic part or adding ribs in the anti - warpage direction can enhance the plastic part's anti - warpage ability.

- Plastic aspects in Plastic Products Production

Crystalline plastics have a higher chance of warpage and deformation than non - crystalline plastics. In addition, crystalline plastics can use the crystallization process in which the degree of crystallinity decreases with the increase of the cooling rate and the shrinkage rate becomes smaller to correct warpage and deformation. This property of plastics is important to consider in plastic products production. - Processing aspects in Plastic Injection Molding

Excessively high injection pressure, too long holding time, too low melt temperature and too fast speed will increase internal stress and cause warpage and deformation in plastic parts.

Too high mold temperature and too short cooling time will cause the plastic part to be overheated during demolding and result in ejection deformation.

Under the condition of maintaining the minimum filling amount, reducing the screw rotation speed and back pressure to reduce the density and limit the generation of internal stress is a processing technique in plastic injection molding.

If necessary, the plastic parts prone to warpage and deformation can be post - molded after demolding or annealed after demolding.

IV. Analysis of Color Streaks, Color Lines and Color Blotches in Injection - Molded Plastic Products

Increasing the temperature of the feeding section, especially the temperature at the rear end of the feeding section, so that it is close to or slightly higher than the temperature of the melting section, so that the masterbatch can melt as soon as possible when it enters the melting section, promote uniform mixing with the diluent, and increase the chance of liquid - state mixing is a solution in plastic injection molding for color - related issues.

Under the condition of a certain screw rotation speed, increasing the back - pressure so that the melt temperature and shear effect in the barrel are improved can also help in achieving more uniform color in plastic products.

V. Cause Analysis of Shrinkage and Sink Marks in Injection - Molded Plastic Parts

- Machine aspects in Plastic Parts Production

If the nozzle hole is too large, melt backflow will occur and cause shrinkage in plastic parts. If it is too small, the resistance is large and the material quantity is insufficient, also causing shrinkage.

Insufficient clamping force causing flash will also lead to shrinkage in plastic parts. Checking whether there is a problem with the clamping system is necessary in plastic parts production.

Insufficient plasticizing amount. Selecting a machine with a larger plasticizing capacity and checking whether the screw and barrel are worn are important steps in plastic parts production.

- Mold aspects in Mold Manufacturing

The product design of plastic parts should ensure a uniform wall thickness to ensure consistent shrinkage. This is an important aspect of plastic injection mold design.

The cooling and heating systems of the plastic injection mold should ensure the same temperature in all parts.

The gating system of the plastic injection mold should be unobstructed, and the resistance should not be too large. For example, the dimensions of the main runner, sub - runner and gate should be appropriate, the surface finish should be sufficient, and the transition area should have an arc transition.

For thin - walled plastic parts, increasing the temperature to ensure smooth material flow, and for thick - walled plastic parts, reducing the mold temperature are effective measures.

The gates should be symmetrically arranged, preferably at the thick - walled parts of the plastic part, and the volume of the cold - slug well should be increased.

- Plastic aspects in Plastic Products Production

Crystalline plastics shrink more severely than non - crystalline plastics. During processing, increasing the material quantity appropriately or adding a nucleating agent to the plastic to accelerate crystallization and reduce shrinkage and sink marks are methods in plastic products production. - Processing aspects in Plastic Injection Molding

If the barrel temperature is too high, the volume change is large, especially the front furnace temperature. For plastics with poor fluidity, increasing the temperature appropriately to ensure smooth flow is necessary in plastic injection molding.

If the injection pressure, speed, back - pressure are too low, and the injection time is too short, the material quantity or density is insufficient and causes shrinkage. If the pressure, speed, back - pressure are too large and the time is too long, flash will occur and cause shrinkage.

If the feeding amount, that is, the cushion is too large, it will consume the injection pressure. If it is too small, the material quantity is insufficient.

For plastic parts that do not require high precision, after the injection and holding are completed, when the outer layer is basically condensed and hardened and the core part is still soft and the plastic part can be ejected, demolding it as early as possible and letting it cool slowly in air or hot water can make the shrinkage and sink marks less obvious without affecting the use.

VI. Cause Analysis of Transparency Defects in Injection - Molded Plastic Products

Eliminating the interference of gas and other impurities and fully drying the plastic is the first step in solving transparency defects in plastic products.

Lowering the material temperature, adjusting the barrel temperature in sections, and appropriately increasing the mold temperature can help.

Increasing the injection pressure and reducing the injection speed can also improve the situation.

Increasing or decreasing the pre - plasticizing back - pressure and reducing the screw rotation speed are methods to deal with transparency issues in plastic injection molding.

Improving the exhaust conditions of the runner and cavity, cleaning the possible blockages in the nozzle, runner and gate, shortening the molding cycle, and annealing after demolding can all help in eliminating silver streaks in transparent plastic products.

VII. Cause Analysis of Color Non - uniformity in Injection - Molded Plastic Products

Poor diffusion of the colorant, which often causes patterns near the gate. This requires better colorant distribution in plastic injection mold design.

Poor thermal stability of the plastic or colorant. Fixing the production conditions, especially the material temperature, material quantity and production cycle, is crucial in plastic products production to stabilize the color.

For crystalline plastics, making the cooling rate of each part of the plastic product consistent, using colorants to mask the color difference for products with large wall - thickness differences, and fixing the material temperature and mold temperature for products with relatively uniform wall - thickness are important measures.

The shape of the plastic product and the form and position of the gate affect the plastic filling situation, causing color differences in some parts of the product. Modifying the product design or gate position may be necessary.

VIII. Cause Analysis of Color and Gloss Defects in Injection - Molded Plastic Products

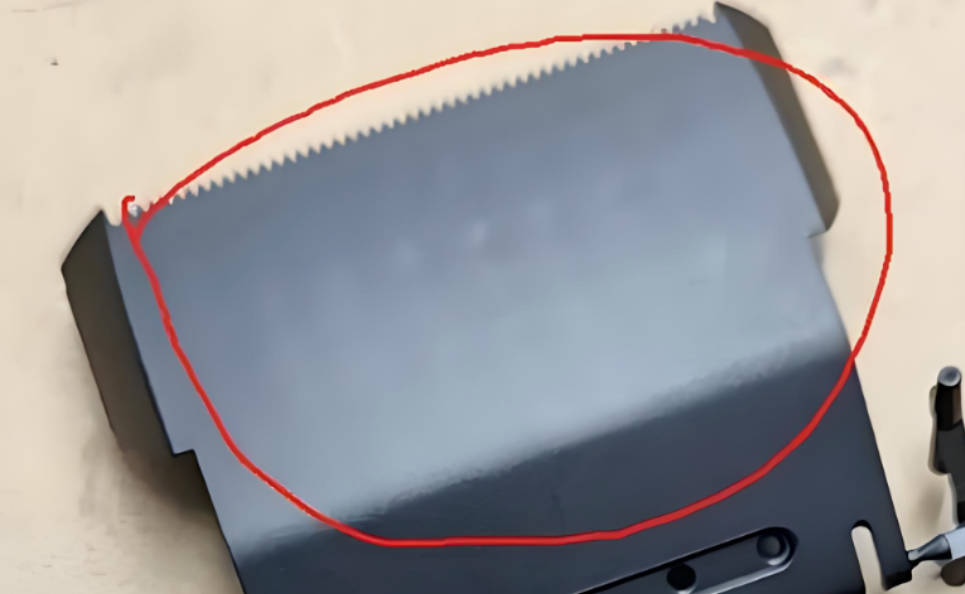

Poor mold surface finish, rust on the cavity surface, and poor mold exhaust can lead to color and gloss defects in plastic products.

Defects in the gating system of the plastic injection mold. Increasing the cold - slug well, increasing the runner, and polishing the main runner, sub - runner and gate can improve the situation.

Low material temperature and mold temperature can cause color and gloss problems in plastic products.

Low processing pressure, slow speed, insufficient injection time, and insufficient back - pressure result in poor compactness and a dull surface in plastic products.

Fully plasticizing the plastic, preventing material degradation, ensuring stable heating and sufficient cooling, especially for thick - walled plastic products, are important in plastic injection molding.

Preventing cold material from entering the plastic product, changing to a self - locking spring nozzle or lowering the nozzle temperature if necessary can solve color and gloss issues.

Excessive use of recycled material, poor quality of plastic or colorant, mixed with water vapor or other impurities can cause color and gloss defects.

Ensuring sufficient clamping force is necessary to avoid these defects in plastic products.

IX. Cause Analysis of Silver Streaks in Injection - Molded Plastic Parts

- Machine aspects in Plastic Parts Production

Wear of the barrel and screw, or the existence of dead - flow areas at the rubber - passing head and rubber - passing ring, which are decomposed after being heated for a long time. This can be a problem in plastic parts production.

The heating system being out of control, resulting in excessive temperature and decomposition. Checking heating elements such as thermocouples and heating coils is necessary. Improper screw design can also introduce air.

- Mold aspects in Mold Manufacturing

Poor exhaust in the plastic injection mold can cause silver streaks in plastic parts.

High friction resistance in the runner, gate and cavity of the plastic injection mold causes local overheating and decomposition.

Unbalanced distribution of gates and cavities, and unreasonable cooling systems in the plastic injection mold will cause uneven heating, resulting in local overheating or blocking of the air passage.

Leakage of the cooling passage into the cavity can lead to silver streaks in plastic parts.

- Plastic aspects in Plastic Products Production

High humidity of the plastic, excessive proportion of recycled material added, or the presence of harmful scrap (scrap is extremely easy to decompose) in plastic products production can cause silver streaks.

Absorbing moisture from the atmosphere or from the colorant. Drying the colorant and installing a dryer on the machine can help.

Excessive or uneven mixing of lubricants, stabilizers, etc. added to the plastic, or the plastic itself containing volatile solvents. Decomposition may also occur when it is difficult to balance the heating degree of mixed plastics.

The plastic being contaminated and mixed with other plastics can lead to silver streaks in plastic parts.

- Processing aspects in Plastic Injection Molding

Setting too high temperature, pressure, speed, back - pressure and melt motor speed causes decomposition. Or when the pressure and speed are too low, injection time and holding are insufficient, and back - pressure is too low, due to the failure to obtain high pressure, the density is insufficient and the gas cannot be dissolved, resulting in silver streaks. Appropriate setting of temperature, pressure, speed and time, and adopting multi - stage injection speed are important in plastic injection molding.

Low back - pressure and high rotation speed allowing air to enter the barrel and then enter the mold

- with the melt, and long cycle times causing the melt to be heated for too long in the barrel and decompose can lead to silver streaks.

Insufficient material quantity, too large feeding cushion, too low material temperature or too low mold temperature all affect the material flow and molding pressure, promoting the generation of silver streaks in plastic parts.

X. Cause Analysis of Weld Lines in Injection - Molded Plastic Parts

- When molten plastic converges in multiple strands in the cavity of a plastic injection mold due to encountering inserts, holes, areas with inconsistent flow velocities, or areas where the filling material flow interrupts, linear weld lines are generated due to incomplete fusion. In addition, weld lines will also be generated when gate jet filling occurs. The strength and other properties at the weld lines are very poor. The main reasons are analyzed as follows:

- Processing aspects in Plastic Injection Molding

Low injection pressure and speed, low barrel temperature and mold temperature cause the melt entering the mold to cool too early and form weld lines in plastic parts.

When the injection pressure and speed are too high, jetting occurs and weld lines are formed.

Increasing the rotation speed and back - pressure to reduce the plastic viscosity and increase the density can help reduce weld lines.

Well - drying the plastic, using less recycled material, and avoiding excessive or poor - quality demolding agent can prevent weld lines in plastic parts.

Reducing the clamping force to facilitate exhaust can also be beneficial in dealing with weld lines.

- Mold aspects in Mold Manufacturing

Too many gates in the same cavity of the plastic injection mold. Reducing the number of gates, or symmetrically arranging them, or setting them as close as possible to the weld lines can be a solution.

Poor exhaust at the weld line. Setting up an exhaust system in the plastic injection mold is necessary.

The runner being too large, inappropriate size of the gating system. When setting the gate, avoiding the melt flowing around the insert holes or using inserts as little as possible can help.

Excessive wall - thickness variation or too thin wall - thickness. Making the wall - thickness of the plastic part uniform can reduce weld lines.

If necessary, setting a fusion well at the weld line to separate the weld line from the plastic part (flash block) can be an effective measure.

- Plastic aspects in Plastic Products Production

For plastics with poor fluidity or heat - sensitivity, adding appropriate lubricants and stabilizers can be helpful in plastic products production.

If the plastic contains a lot of impurities, replacing it with high - quality plastic may be required.

XI. Cause Analysis of Vibration Marks in Injection - Molded Plastic Parts

- On the surface of rigid plastic parts such as those made of PS near the gate, dense ripples are formed centered on the gate, sometimes called vibration marks. The reason is that when the melt viscosity is too high and fills the mold in a stagnant flow form, the front - end material quickly condenses and shrinks when it comes into contact with the cavity surface, and the subsequent melt expands the shrunk cold material and continues to move forward. The continuous alternation in this process forms surface vibration marks.

- Solutions:

Increasing the barrel temperature, especially the nozzle temperature, and also increasing the mold temperature can reduce vibration marks.

Increasing the injection pressure and speed to fill the mold cavity quickly is an effective solution.

Improving the size of the runner and gate to prevent excessive resistance can help.

Ensuring good exhaust in the plastic injection mold and setting a large enough cold - slug well are also important.

XII. Cause Analysis of Swelling and Blistering in Injection - Molded Plastic Parts

- Some plastic parts, soon after demolding, develop swelling or blistering on the back of metal inserts or in particularly thick parts. This is because the plastic that has not been completely cooled and hardened expands due to the release of gas under internal pressure.

- Solutions:

Effective cooling: reducing the mold temperature, extending the mold - opening time, and lowering the drying and processing temperature of the material.

Reducing the filling speed, shortening the molding cycle, and reducing the flow resistance.

Increasing the holding pressure and time.

Improving the situation where the plastic part wall is too thick or has a large wall - thickness variation.