Explore how the concealed submarine (hidden) gate enhances part appearance, automates gate removal, and optimizes plastic injection mold design and Thermoplastic Injection production.

In modern plastic part production—spanning plastic injection mold design, injection mould tool design and Thermoplastic Injection—the submarine gate (or hidden gate) plays a vital role. Located inside ribs, bosses or non–visual surfaces, this gate type combines aesthetic advantage with process efficiency, making it a go-to choice for high–precision, multi–cavity Mold Manufacturing.

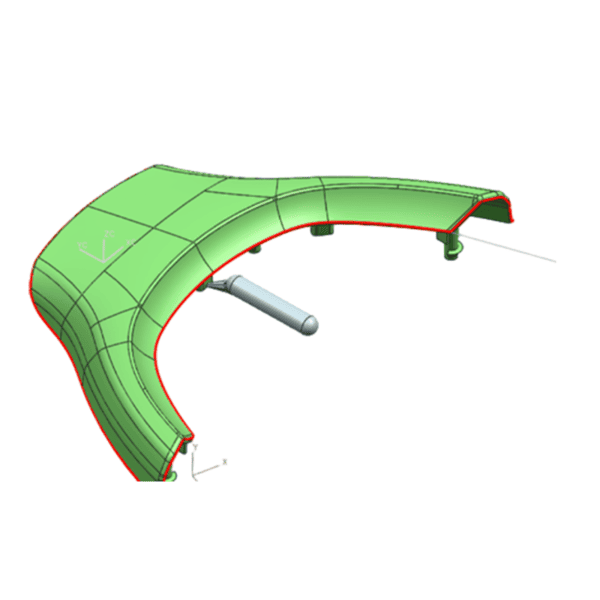

What Is a Submarine Gate?

Also called a tunnel or buried gate, the submarine gate is machined into the mold cavity such that the point of entry is hidden within the molded part. During ejection, a mechanical stripper pin or ejector automatically severs the gate at its thin section—eliminating manual trimming and scrap.

Key Advantages

• Improved Appearance

– No visible vestige on the part’s exterior surface

• Automated Gate Separation

– Streamlines Thermoplastic Injection workflow by cutting off the gate during mold opening

• Consistent Part Quality

– Reduces flash and gate vestige, enhancing repeatability in high–volume Mold Manufacturing

• Suitable for Multi-Cavity Modules

– Consistent fill-balance in small-to-medium parts with rigorous plastic injection mold design requirements

Design Considerations

a. Gate Location & Angle

– Position below ribs or bosses to hide gate mark and maintain uniform melt flow.

b. Gate Diameter & Land Length

– Optimize small gate cross-section and short land to ensure easy break-off without back-pressure issues.

c. Material Fluidity & Cooling

– Adapt gate geometry to thermoplastic viscosity in Thermoplastic Injection; ensure proper cooling channel layout to prevent stress concentration.

d. Tooling Precision

– High-accuracy injection mould tool design and machining tolerances (< 0.01 mm) in the gate region are critical to control gate size and thickness.

Application Scenarios

• Consumer electronics housings where surface finish matters

• Automotive interior trim featuring invisible gating

• Medical device components requiring automated demolding

• Small molds with dozens of cavities for rapid turn-over production

Conclusion

The submarine gate offers a blend of cosmetic excellence and process automation that directly supports advanced plastic injection mold design, injection mould tool design and large-scale Mold Manufacturing. By carefully balancing gate geometry, material properties and thermoplastic flow, manufacturers can leverage this hidden-gate solution to deliver high-quality, appearance-driven parts with minimal secondary processing.