04-26/2025

CNC Machining Prototype Parts: The Future of Rapid Product Development

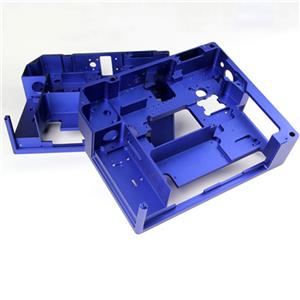

CNC machining prototype parts have revolutionized manufacturing timelines across industries. CNC machining prototype parts deliver unmatched precision in record timeframes. The aerospace sector relies on CNC machining prototype parts for flight-critical components. Medical device developers use CNC machining prototype parts for FDA-approved trial units. Automotive engineers test CNC machining prototype parts in wind tunnels within 72 hours.

More