02-28/2025

The Future of Plastic Part Manufacturing: Innovations Driving Efficiency, Precision, and Sustainability

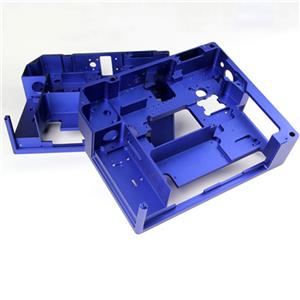

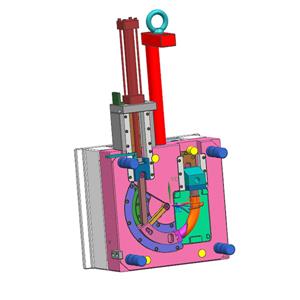

The plastic parts production industry is undergoing a radical transformation. As sectors ranging from automotive and aerospace to consumer electronics and medical devices demand lighter, stronger, and more cost-effective plastic products, manufacturers are adopting groundbreaking methods to stay competitive. This deep dive explores the cutting-edge technologies reshaping plastic products creation, with particular focus on low volume production of the plastic parts, advanced moulding techniques, and sustainable practices adopted by forward-thinking plastic parts factory operations worldwide.